RBC Ball Bearings Mounting Arrangements

RBC thin section ball bearings are engineered to solve a variety of design problems that cannot be solved with conventional ball bearings.

General Information

MOUNTING ARRANGEMENTS

When selecting a mounting arrangement for RBC Thin Section Ball Bearings, you must first consider the loading condition. A duplex pair of angular contact bearings may be used for combined loading, moment loading, or heavy thrust loading. Combination A and C-Type, A and X-Type, or C and X-Type bearings are common mounting arrangements. Two X-Type bearings should never be mounted on the same shaft. There may be many different bearing arrangements for carrying the same load, some typical mounting arrangements are shown below.

Heavy Radial Loads

The C-Type bearing is designed primarily for heavy radi¬al loads. Two bearings can be installed on the same shaft as shown. By axially fixing one bearing and allow¬ing the other to float, this configuration allows differen¬tial expansion between the housing and shaft, such as caused by temperature difference, without adding axial stress to the bearings. Although the C-Type bearing is designed for radial loads, they can withstand moderate thrust, moment and reversing loads.

Reversing Loads

The duplex pair of A-Type bearings offers several configurations. For reversing loads, either Back-to-Back, B-Type, or Face-to-Face, F-Type, should be used. The F-Type mounting method demonstrates reversing thrust load. Combined radial and thrust loads are shown on the B-Type configuration. Both of these methods can be used for heavy radial loads, combined thrust and radial loads, or moment loads.

Alternate mountings for heavy combined loading or moment loading are shown below. A duplex pair of B-Type bearings resists high thrust, radial and moment loads. An X-Type bearing may replace the duplex pair in less heavily loaded applications for weight, space and cost savings.

Heavy Combined Loading

For heavy combined loading other special mounting arrangements may be employed. As shown in the top drawing, a duplex pair of A-Type bearings can be used with a floating C-Type bearing. In this configuration the A-Type bearings will carry the thrust load and part of the radial load while the C-Type carries only radial load. An X-Type bearing can replace the duplex pair of A-Type bearings to carry lower thrust loads as shown in the second drawing.

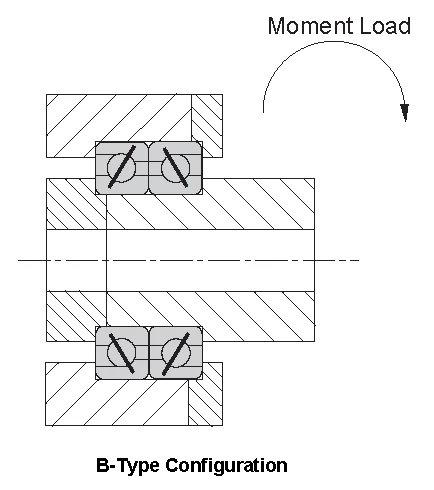

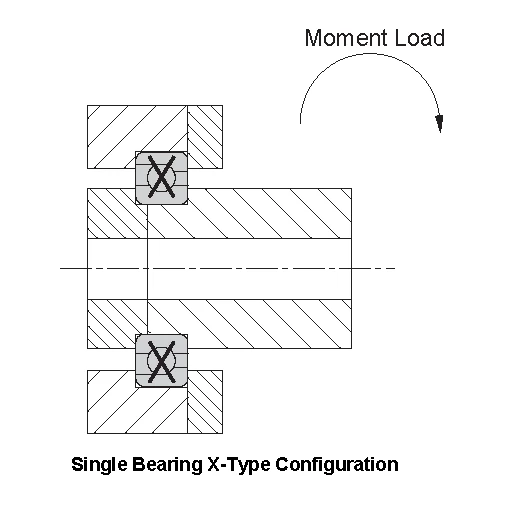

Heavy Combined Loading or Moment Loading

Alternate mountings for heavy combined loading or moment loading are shown below. A duplex pair of B-Type bearings resists high thrust, radial and moment loads. An X-Type bearing may replace the duplex pair in less heavily loaded applications for weight, space and cost savings.