Schnorr Disc Springs

SPRING PARAMETERS FOR DIMENSIONS & CALCULATION

Disc Spring Engineering

Maximum load - minimum space - maximum flexibility

Menu

SPRING PARAMETERS FOR DIMENSIONS & CALCULATION

SPRING PARAMETERS FOR DIMENSIONS & CALCULATION

Disc springs are determined essentially by the following three parameters:

δ = Outside diameter De

Inner diameter Di

Ho/t =

Cone height Io – t

Disc thickness t

De/t = Outside diameter De

Disc thickness t

If at all possible, the parameters above should be within the following values:

δ = 1.75…2.5

ho/t = 0.4…1.3

De/t = 16…40

For smaller values δ, smaller values of ho/t and De/t also apply and vice-versa.

For steel springs with dimensions within these limits, formula 7 can be used without restriction. For very thin disc springs (De/t > 50) the formula results in spring forces which are too high.

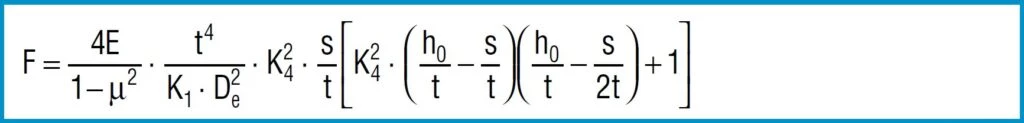

Formula 7

For very narrow disc washers with a ratio of diameters of De/Di < 1.75, the shortening of the lever arm must be considered when calculating the force. This is brought about by the rectangular cross-section and by the rounded edges and results in the calculation of too low a load. In all such cases please contact us.