Schnorr Disc Springs

DISC SPRINGS WITH CONTACT FLATS AND REDUCED THICKNESS

Disc Spring Engineering

Maximum load - minimum space - maximum flexibility

DISC SPRINGS WITH CONTACT FLATS AND REDUCED THICKNESS

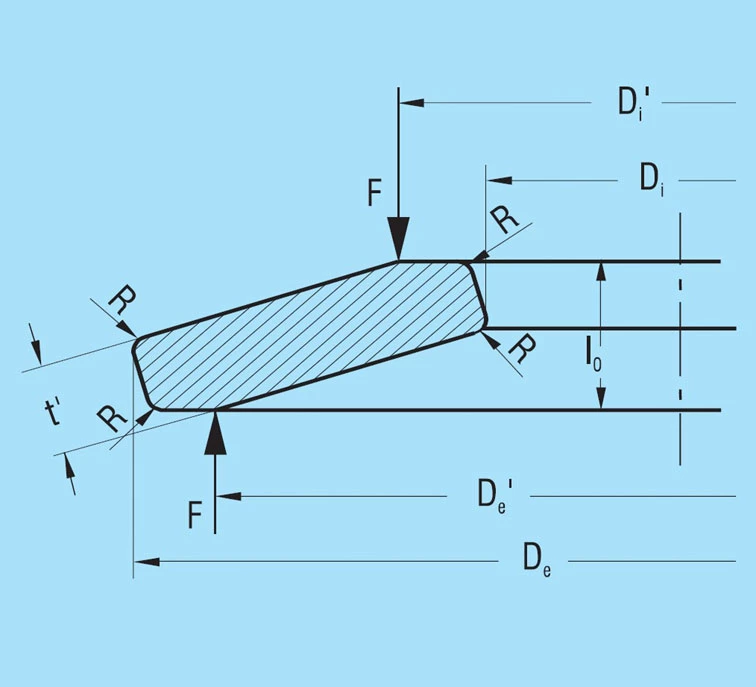

For disc springs with a thickness of more than 6.0mm, DIN 2093 specifies small contact surfaces at points l and lll in addition to the rounded corners. Figure 5 shows a schematic cross-section of a spring in group 3 as per DIN 2093. The corresponding springs of our factory standard are also manufactured in the same manner.

Figure 5 – click to enlarge

These contact flats improve definition of the point of load application and, particularly for spring stacks, reduce friction at the guide rod. The result is a considerable reduction in the lever arm length and a corresponding increase in the spring load. This is in turn compensated for by a reduction in the spring thickness from t to t’.

When calculating disc springs with contact flats and reduced thickness, the factor K4 must be calculated using formula 6, and t replaced with t’ and ho with ho’ = lo – t’ in the equations 7 to 16.

The reduced thickness t’ is specified in accordance with the following conditions:

- The overall height lo remains unaltered

- The width of the contact flats is to be approximately 1/150 of the outside diameter

- The spring load for a reduced thickness spring must be the same at s = 0.75 ho as for an unreduced spring

The dimension t’ is specified for those discs springs contained in DIN 2093. The mean factor t’/t is:

| Series | A | B | C |

| t’/t | 0.94 | 0.94 | 0.96 |

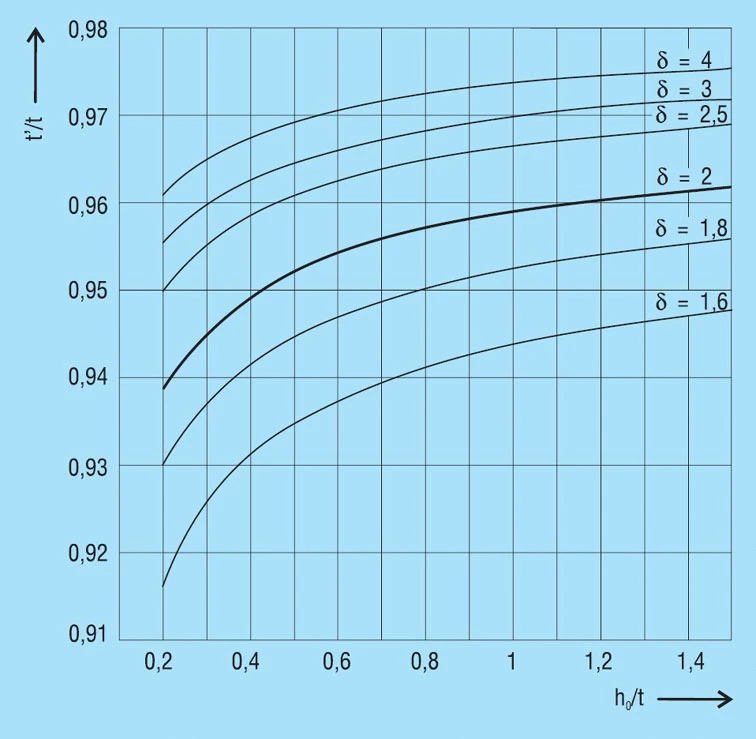

For other springs the factor for t’/t is dependent on the dimensional ratio δ and ho/t from figure 6. The curves were calculated for disc springs with δOM = -1600N/mm2. For springs with different stress sOM, we would ask you to contact us on 01202 339559.

As the overall height is not reduced, springs with reduced thickness inevitably have an increased flank angle and a greater cone height ho’ than springs of the same nominal dimension without reduced thickness. Therefore, the characteristics curve is altered and becomes more curved. Figure 7 shows the characteristic curves for springs of the series A, B and C as per DIN 2093 with and without contact flats and reduced thickness.

Figure 6 – click to enlarge