Schnorr Disc Springs

Calculation for a single spring

Disc Spring Engineering

Maximum load - minimum space - maximum flexibility

CALCULATION FOR A SINGLE SPRING

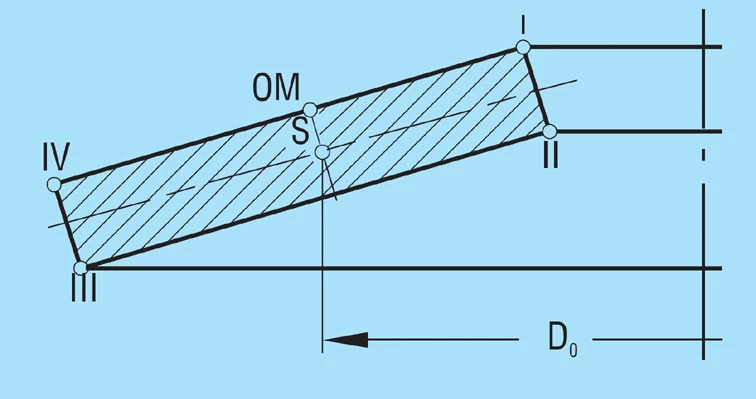

The calculations of Almen and Laszlo assume that a spring flank rotates around a centre of rotation during deflection, placed in the centre of the spring flank at diameter Do.

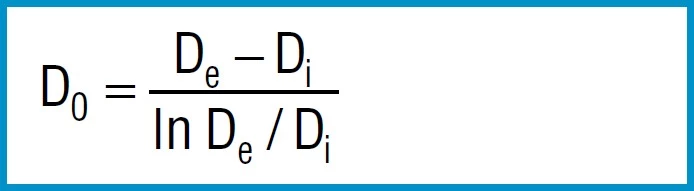

Formula 1

The rotation of the cross section is the reason for the various stresses and the spring effect.

The calculations assume that Young’s modulus ‘E’ remains linear for the material, the spring cross-section is rectangular with sharp corners and the spring remains in one plane during deflection. The load is applied at points l and lll. There is residual stress in the spring after being manufactured and heat treated and can be ignored.

Although today there are more accurate methods of calculation, there is no reason to abandon the simple and convenient formulas of DIN 2092. For standard dimensions they produce values which correspond well to the measured results.

Figure 2 – click to enlarge