Schnorr Disc Springs

Schnorr Disc Springs Calculation Examples

Disc Spring Engineering

Maximum load - minimum space - maximum flexibility

Basic Calculation Examples

The ‘life lines’ also allow the fatigue life to be estimated for various working strokes. In spite of this we show several examples of the calculation and checking of disc springs below.

Example 1: Checking fatigue life of a disc spring

Given:

Spring 45 x 22.4 x 1.75; lo = 3.05mm (figure 11)

Preload F1 = 1580N

Final Load F2 = 2670N

Frequency f = 1000/min

To be determined:

Is the stress within the acceptable range – what is the estimated fatigue life.

Solution:

From the tables of disc springs we can obtain the following data:

s/ho s[mm] F[N] s[N/mm2]

0.25 0.325 1524 433

0.5 0.650 2701 814

0.75 0.980 3659 1148

1.0 1.300 4475 1421

With the help of these four points the load and stress relative to the deflection may be drawn.

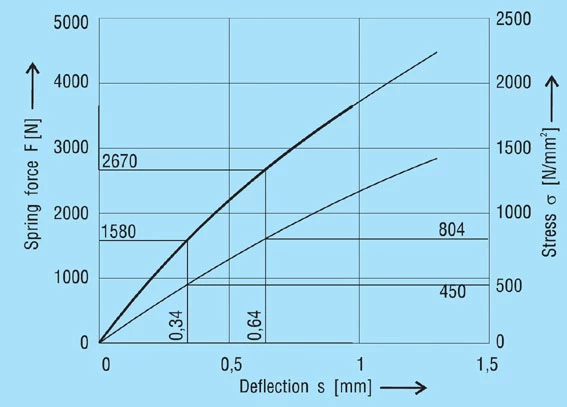

Figure 11 – click to enlarge

Disc spring 45 x 22.4 x 1.75; lo = 3.05 mm

The following values may be obtained from the diagram (figure 12):

S1 = 0.34mm, S2 = 0.64mm

σu = 450 N/mm2

σo= 804 N/mm2

From the fatigue diagram for group 2 springs figure 19, we obtain σu 450 N/mm2 with a maximum stress of σ0= 920 N/mm2. Therefore the spring is fatigue resistant as σo < σ0.

Figure 12 – click to enlarge

Diagram for spring 45 x 22.4 x 1.75 mm, lo = 3.05 mm

Example 2: Disc spring with a high ho/t ration

Given:

Guide diameter 30mm

Installed length l1 = 4,9mm

Preload F1 = 2000 N min.

Working defl. s2 – s1 = 1.05mm

Spring load F2 = 2500 N max.

Required:

Suitable disc spring dimensions

Solution:

Spring inside diameter Di = 30.5mm

Spring outside diameter De = 60mm (selected because of the favourable De/Di ratio)

Because of the very small load range and the small installed length only a spring with a high ho/t ratio is suitable.

Selected:

Disc spring 60 x 30.5 x 1.5mm (figure 13); lo = 3.5mm ho/t = 1.333; δ = 1.967

Calculation:

First the factors are calculated using formula 3, 4 and 5:

K1 = 0.688

K2 = 1.212

K3 = 1.365

Figure 13 – click to enlarge

Disc spring 60 x 30.5 x 1.5 mm

The stress σOM can be checked using formula 9: σOM = -1048 N/mm2.

This value lies well under the limit of -1600 N/mm2, the spring will therefore not set. Now the spring loads can be calculated to formula 8a, preferably for the 4 deflections s = 0.25 ho, s = 0.5 ho, s = 0.75 ho and s = ho.

One obtains the following values:

s/ho s[mm] F[N]

0.25 0.5 1338

0.5 1.0 2058

0.75 1.5 2367

1.0 2.0 2469

With these 4 points the spring diagram can be drawn.

Figure 14 – Click to enlarge

Diagram for spring 60 x 30.5 x 1.5 mm, lo = 3.5 mm

One can read F1 = 2100 N s1 = 1.05mm

and for F2 = 2400 N s2 = 1.61mm

Deflection s2 – s1= 0.56mm

The deflection of a single spring is not sufficient, therefore two in series must be used.

This arrangement gives:

Unloaded length Lo=7.0mm

Preloaded length L1=4.90mm

Preloaded deflection s1=2.1mm

Preload F1=2100N

Deflection s2=s1+1.05=3.15mm

Final load F2=2390N

To check the fatigue life we must use the stresses at s1 = 1.05 and s2 = 1.575mm. Figure 17 shows that point lll is the dominant one, this gives:

s1: σu = 843 N/mm2

s2: σu = 1147 N/mm2

By utilising the fatigue life diagram in figure 19 we can see that the expected life will be in the order of 1,000,000 cycles.

Example 3: Calculation of a disc spring with contact flats

Given:

Disc spring 200 x 82 x 12mm; lo = 16.6mm

Ho = 4.6mm; δ = 2.439; ho/t = 0.383

Required:

The spring characteristics and the stresses σll and σlll.

Although this spring is to our works standard we show below how the calculations are made and results can be checked in the disc springs dimension tables.

From the formula 3 to 5 we first calculate the constants K1 to K3:

K1 = 0.755

K2 = 1.315

K3 = 1.541

The static design can be checked by the calculation of σOM, the reduced thickness is not considered and we use the values of t and ho. This gives:

σOM = -1579 N/mm2

As the acceptable value for σOM is 1600 N/mm2, the spring is correct. From figure 6 and considering d and ho/t the reduction factor t’/t can be obtained:

t’/t = 0.958

Therefore t’ = 11.5mm and ho’ = 5.1mm. Constant K4 can be calculated from formula 6: K4 = 1.0537.

Figure 15 – Click to enlarge

Disc spring 200 x 82 x 12 mm

Figure 16 – click to enlarge

Spring force and stresses for spring 200 x 82 x 12 mm, t’ = 11.5 l0 = 6.6 mm

Now from formula 8b, 11 and 12 the spring force and both stresses can be calculated.

s/ho s[mm] F[N]

σll

[N/mm2]

σlll

[N/mm2]

0.25 1.15 66924 416 389

0.5 2.3 127191 890 747

0.75 3.45 182838 1421 1072

1.0 4.6 235503 2011 1366

With this spring the greater values of stress are on the inner diameter which should be used. Finally the value of the stress σOM for the reduced thickness can be checked:

σOM’ = σOM . K4 . t’/t

σOM’ = -1595 N/mm2